By Danielle Campbell

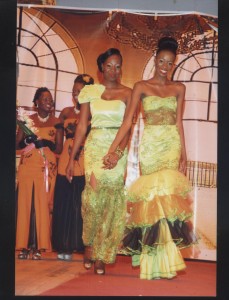

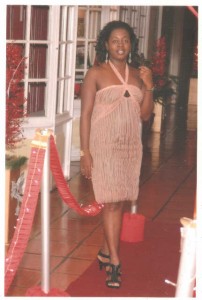

Dancing and sewing are two of Roxanne King’s innermost passions. In fact, she is lucky enough to have her two favourite pastimes as the professions from which she earns her upkeep. King has had her fair share of good and bad experiences, but they have only served to fortify her resilient spirit and prepare her for life as a model entrepreneur.

She is a fourth-generation seamstress who developed her innate skill to manufacture neatly-designed pieces. But King was not always successful. She started working at home as a seamstress in 1987.

Comments are closed.