– Bhim says production shortfalls being addressed

By Michael Younge

The Guyana Sugar Corporation (GuySuCo) said it has taken aggressive measures to improve its profitability while at the same time creating a more efficient management structure that would result in improved production.

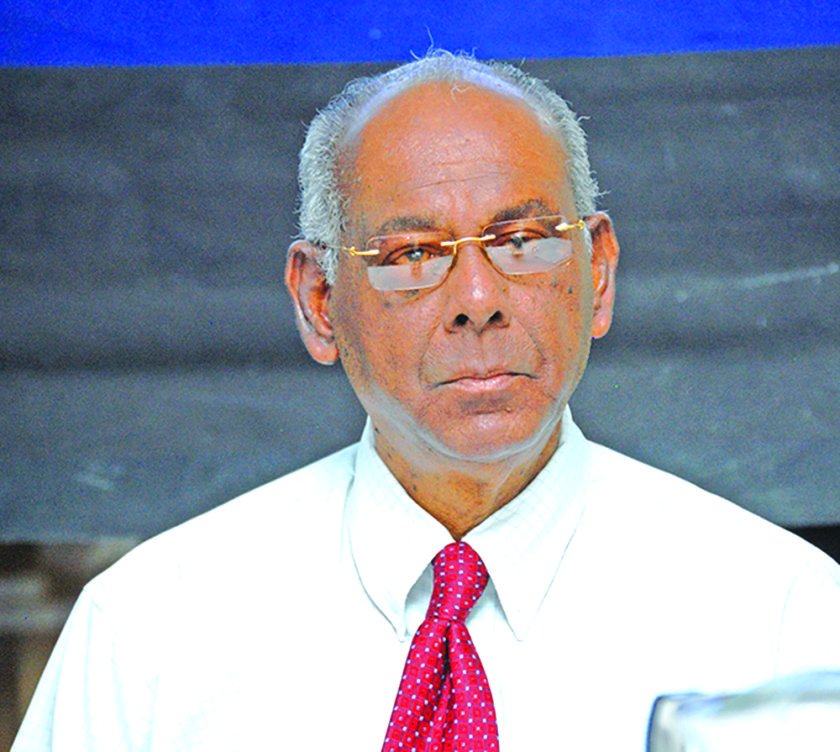

The entity has been the centre of public criticisms for its inability to get its act together and address competently its shortfalls while at the same time meeting its set goals and objectives. The corporation’s Chief Executive Officer Paul Bhim speaking in a recent interview with Guyana Times International on Wednesday afternoon said while many of the old problems plaguing the industry have not been fully addressed, he is satisfied with the gains made by management in a number of areas.

“When I took over from the previous CEO, Booker Tate had just gone and we were in the process of building a new management team and I think that has gone quite well,” he said.

Bhim explained that the new managers are in place and have gained “quite a bit of experience” as he noted that more changes can be expected under their leadership over the next few years. He was convinced that the entity had managed to create “stability” within its senior management rank which has led to better management of resources that fall under the direct control of the sugar company.

The CEO also pointed to the entity’s ability to commission and make fully operational the new Enmore Packaging Plant, which could package more than 40,000 tonnes of sugar per year for specific markets. “There are ready markets for that sort of sugar and it does fetch quite a premium price as well, and so if we can produce the sugar, we can certainly sell it, and we can sell it at a very good price,” Bhim noted.

Comments are closed.