…cites struggling global bauxite market

By Svetlana Marshall

Bosai Minerals Group Guyana Incorporated (BMGGI) on Tuesday said it has shelved its US$100 million expansion project owing to the challenges being faced on the global bauxite market.

In 2012, the bauxite company in Linden announced its intention to invest approximately US$40 million to mine additional ore in an area called Block 37, in addition to the construction of a third kiln to the tune of US$57 million. This massive expansion project was designed to create more than 500 jobs in the second largest town in the country, which is said to be starving for job opportunities.

During the 2014 Budget Debate in the National Assembly, Natural Resources and Environment Minister Robert Persaud disclosed that the Government of Guyana took a decision to retain Block 37 due to the challenges faced on the international scene, but Bosai was looking at alternatives.

Slowdown in demand

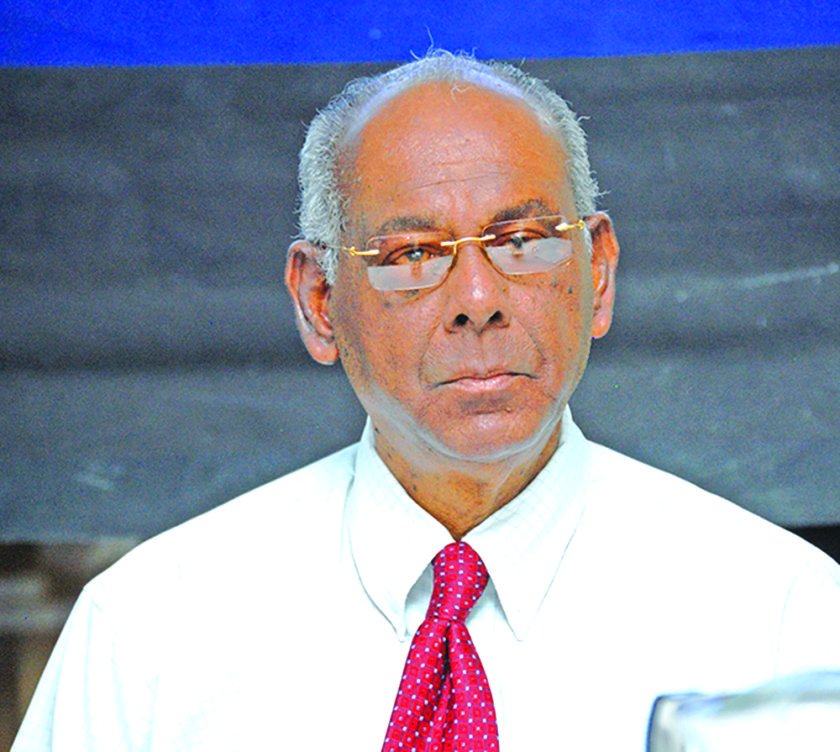

Speaking with Guyana Times International on Tuesday, BMGGI’s General Manager Robert Shang said Bosai has respectfully accepted the Government’s decision. “If that’s the Government’s decision, we are okay with that. Maybe in the future, if we have another expansion plan, maybe we will reapply,” he said.

Shang made it clear, however, that Bosai will not be pursuing the US$100 million expansion project, positing that bauxite remains a challenge. “Right now the global market for calcined bauxite is very, very limited. The global bauxite market is not as good as before. With competition from China, that plan has already been derailed,” Shang told this publication.

Bauxite is the main raw material used in the production of aluminium. Though there are many advantages in producing aluminium, the current supply surplus and the energy-intensive nature of processing aluminium from bauxite have resulted in demand reducing significantly. The situation on the global market is further compounded by the fact that approximately 75 per cent of the material ever smelted is still being used. But despite these challenges, output continues to increase especially in China and Australia, the largest single producers of bauxite.

The Natural Resources Ministry had expressed the view that BMGGI would have moved ahead with the construction of the third kiln, as it seeks alternative mining blocks to develop. Alternative areas such as East Bank Kara Kara and on the West Bank of Linden were identified, but the BMGGI’s General Manager said “it’s just a plan… but we haven’t decided as yet, because we have to do all kinds of feasibility studies.”

Declining production

Currently, Bosai’s operations predominantly take place at the Dacoura and East Montgomery Mines, in Linden, Region 10. Despite the challenges, Shang said the company will not be downsizing its operation. “Guyana bauxite is still good, our quality is good. That is a very good advantage, the market is still there, but it is limited but we are trying our best to maintain this market….the demand is always at a certain level, but we cannot go above that,” he explained.

Questioned about the rate of production for 2013, Shang declined to answer, stating that such information is not given to the press. However in 2013, Bosai disclosed that it had failed to meet its 2012 production target. At the commencement of 2012, Bosai had announced its intention to rake produce 250,000 tonnes of Refractory “A” Super Calcine (RASC) and 150,000 tonnes of the Size Chemical Grade Bauxite (SCGB) by the end of the year. The company later revised the production targets, to 212,000 tonnes for RASC and 150,000 tonnes for SCGB, but even these new targets were not met.

Actual production stood at 205,000 tonnes of RASC and 118,000 tonnes of SCGB when operations closed for 2012. These figures represented production shortfalls of 18 per cent and 21 per cent respectively in terms of the initial targets and 3.3 per cent and 7.09 per cent respectively on the revised targets.

In 2013, it was expected to produce 230,000 tonnes of RASC, 100,000 tonnes of SCGB, and 50,000 tonnes of Cement Grade Bauxite (CeGB). Metallurgical Grade (MAZ) bauxite was expected to be added to the production list. The company was hoping to produce 500,000 tonnes of the material.